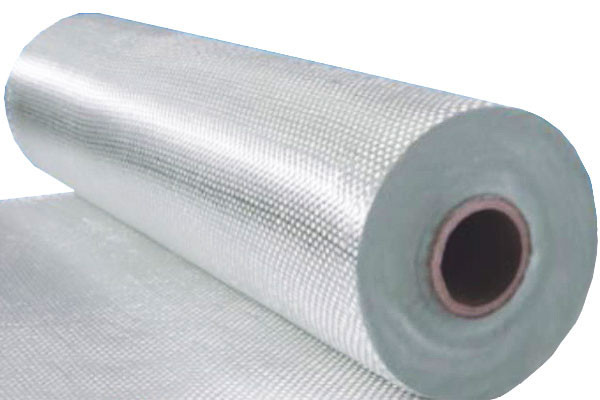

Fiberglass is a type of product that is made of glass

fibers. There are two categories of

glass fibers. One has short fibers that are used in products such as blankets

or boards for filtration or insulation.

The other type is used in textiles and yarns. To make draperies, fiberglass can be made

into yarn and added to fabric just as wool or cotton can be.

Fiberglass textiles help laminated and molded plastics by serving as reinforcement. Fiberglass is also great for sound absorption

and thermal insulation. Fiberglass wool,

which is thick and fluffy works well for this purpose. Car engine compartments, furnaces, air

conditioning units, and ceiling panels are some of the places you can often

find fiberglass textiles.

Fiberglass can be made for specific uses such as electrical insulation tape,

reinforcement and textiles, chemical, and thermal insulation. The use of glass fiber is relatively recent

in history. The raw materials used to

produce fiberglass products include manufactured chemicals and natural

minerals. Most of the ingredients used

include limestone, soda ash, and silica sand. Other ingredients used may include borax, feldspar,

calcined alumina, magnesite, kaolin clay, and nepheline syenite.

To form the glass, silica sand is used and limestone and soda ash mostly aid in

reducing the melting temperature. Some

of the other ingredients are used to enhance the quality. Borax is used for chemical resistance. Cullet (waste glass) is a raw material in the

process. Raw materials need to be

precisely weighed and combined in the batching process before they can be

melted into glass.

After the raw materials are prepared, they are put into a furnace which may be

heated by fossil fuel, electricity, or both.

To have a steady, smooth glass flow, the temperature needs to be

controlled with precision. To be formed

into fiber, the molten glass needs to be at a higher temperature than other

glass types.

The molten glass is taken to the forming equipment. There are a couple of different processes

used to form fibers. The type used

depends on the fiber type. Textile

fibers can be formed from molten glass from the furnace or the glass can be fed

into a machine first. Coatings such as

binders are needed for products made of fiberglass.